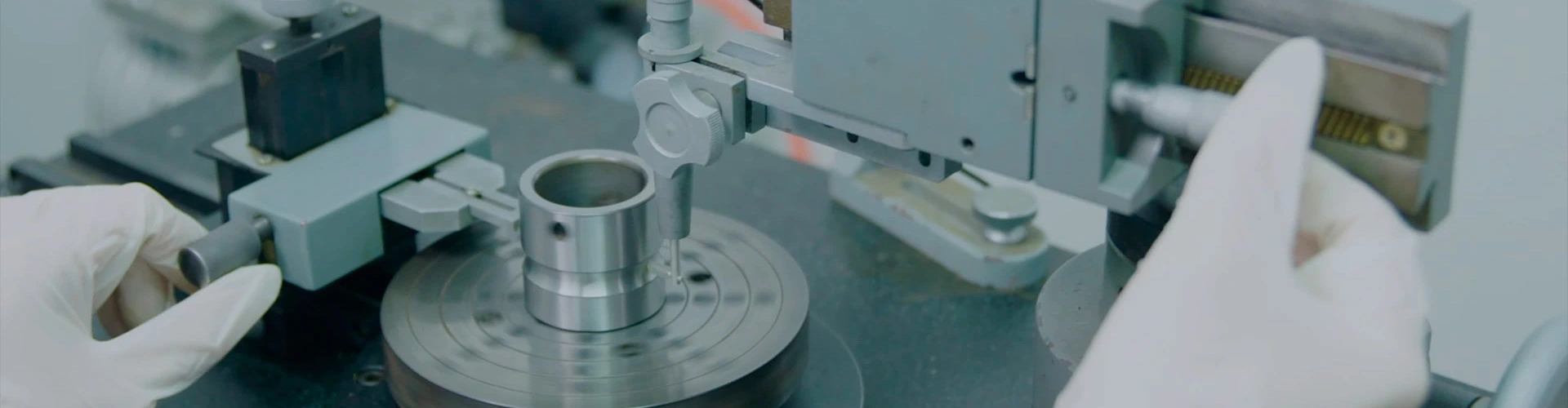

LDK Company implements strict quality control from the arrival of raw materials to the departure of finished products to ensure that the quality of LDK bearings meets customer requirements.

The company possesses advanced testing equipment, measuring instruments, and a physical and chemical material analysis laboratory.

All incoming raw materials undergo inspection and chemical analysis to staunchly avoid second-hand waste or products with unknown origins.

The production process strictly adheres to in-process inspections, including initial inspection, random inspection, and final inspection.

LDK has obtained IATF 16949 certification and has the capability to submit PPAP level 3 documents.