Body and ball made of special plastic polymer (Patent ZL 2009 2 0031919.1)

Maintenance free,self lubricating

High strength under impact loads.

High tensile strength for varying loads.

Compensation for alignment errors.

Resistant to dirt and dust.

Resistant to corrosion of chemicals.

High vibration dampening capacity.

Suitable for rotating,oscillating and linear movements.

Very low weight.

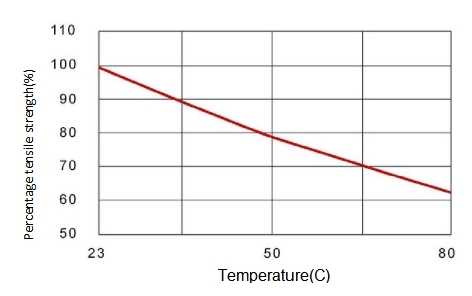

LDK bearing elements can be used in temperatures from -30℃ to+80℃. Table1 shows the effect of temperature on the loading capacity of the LDK bearing elements.

Minimum | -30℃ |

Maximum,long term | +80℃ |

Maximum,short term | +120℃ |

Table 1: Applications temperatures

The moisture absorption of LDK is appro- ximately 1.3% of weight standard atmos- phere.The saturation limit in water is 6.5%. This must betaken into account for these types of applications.LDK all plastic polymer are resistant to weak alkalines, weak acids and fuels,as well as all types of lubricants.

| Medium | Resistance |

| Alcohol | Resistant |

| Chlorinated hydrocarbons | Resietant |

| Ester | Not Resistant |

| Greases,oils | Resistant |

| Ketones | Conditionally Resistant |

| Fuels | Resistant |

| Weak acids | Conditionally Resistant |

| Strong acids | Not Resistant |

| Weak alkalines | Resistant |

| Strong alkalines | Conditionally Resistant |

Table 2: Chemical resistance

The corrosion resistance of the LDK bearings give them special value for outside applications

LDK bearing elements are permanently resistant to UV radiation.A small change in colour (dark coloration)of the spherical ball due to UV radiation does not effect the mechanical,electrical or thermal properties.

The load capacity of the maintenance free LDK bearing elements is very high at normal ambient temperatures.LDK bearing elements absorb high forces and weigh only a fifth of traditional, metal bearing housings. The excellent dampening properties are based on the fact that the polymer material of the two part bearing can absorb vibrations differently than steel.

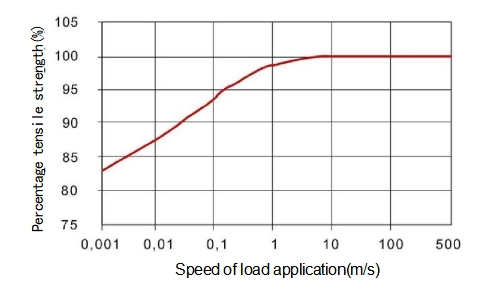

Table 3:Effect of the speed of load application on the maximum tensile strength of LDK rod end bearings

However, plastic specific properties, such as dependence on temperature and behaviour under long term stress, must betaken into consideration when using LDK bearings. The load capacity of the rod end bearing should therefore be checked in a performance test, particularly if they are to be used under continuous high loads and at elevated temperatures.

Table 4: Effect of the temperature on the maximum tensile strength of LDK rod end bearings

One important advantage of LDK spherical bearings is that rapid, rotary movements of a mounted shaft take place directly in the spherical portion, made of special plastic polymer. In metallic rod ends, rotary motion takes place between the race and the spherical bearing. High speeds can be achieved with LDK bearings.

LDK bearings area used in such a way that the angular movements of the spherical bearings takes place at the outer diameter in contrast, rotations of the shaft are supported directly in the I.D. of the spherical portion. The advantage,therefore,lies in the polymer vs.steel relationship. Polymer produces lower friction and permits high speeds, even when running dry.

| Thread Name | Pitch [mm] |

| M2 | 0.4 |

| M3 | 0.5 |

| M4 | 0.7 |

| M5 | 0.8 |

| M6 | 1 |

| M8 | 1.25 |

| M10 | 1.5 |

| M10 F | 1.25 |

| M12 | 1.75 |

| M12 F | 1.25 |

| M14 | 2 |

| M16 | 2 |

| M16 F | 1.5 |

| M18 | 1.5 |

| M20 | 2.5 |

| M20 M20 | 1.5 |

| M22 | 1.5 |

| M24 | 2 |

| M27 | 2 |

| M30 | 2 |

Table 5: Thread pitches of the LDK rod end bearings

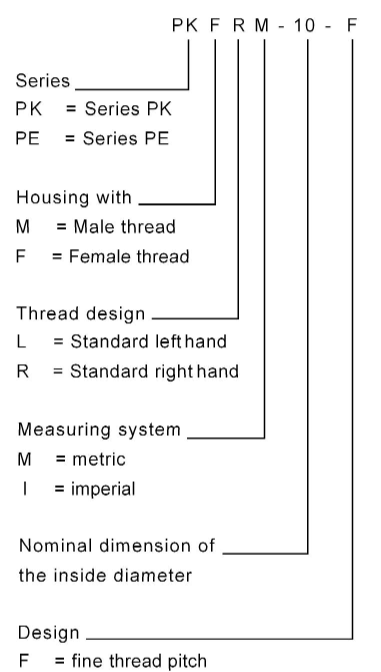

The part numbers of LDK rod end bearings are designed according to the following system:

The example given is the number for a rod end bearing of the dimensional series PK with metric female right hand thread.The inner diameter of the spherical ball is 10mm.