Our technical team of R & D and engineers is highly dedicated to every project received from our clients. We could assist our clients in creating 2D/3D designs based on samples or concepts, effectively bringing their ideas to reality. In the event of any defects, our team can provide professional advice and make rapid modifications to every project.

PPAP 3

From carefully chosen materials to optimized technique, from advanced manufacturing and inspection facilities to rigorous process control, and from robust R & D capabilities to a highly trained team, every detail contributes to LDK's consistently high level of product quality.

Custom made to your print (material, finish, tolerance, configuration), sample or concept.

Private labelling.

Per your specific packaging specification.

Tracibility (Production date, QR code, Barcode).

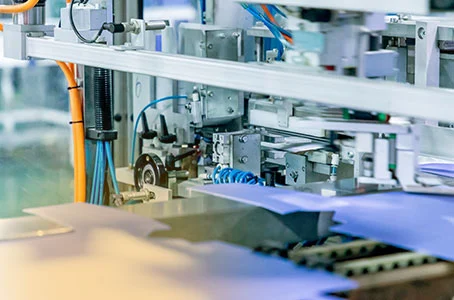

Advanced production equipment allows us to complete all manufacturing processes within ONE FACTORY, IN ONE PLACE.

Automated casting production line.

Housing machining.

Automatic painting line.

Injection molding machines.

Heat treatment production line.

Automated grinding production line.

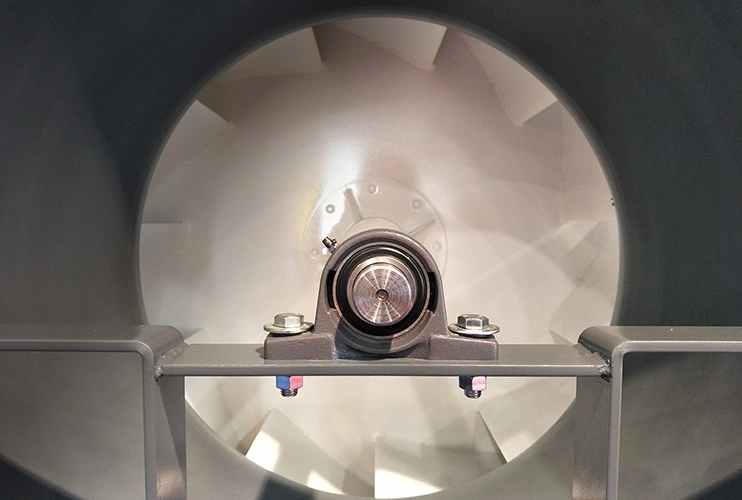

Dust-free bearing assembly line.

Robotic lathe lines, manipulator assembly line, and non-standard product fabrication lines for rod end manufacturing sector.

Fatigue life, Tensile strength, Noise & Vibration and Salt Spray testing.

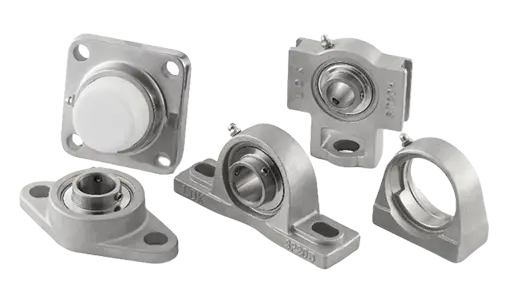

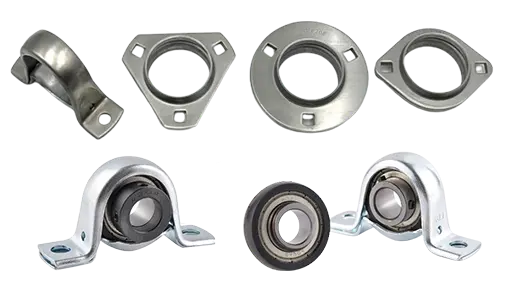

Deyuan Smart Technology (Fujian) Co., Ltd is the high-Tech enterprise and professional manufacturer with a total of 30 years of history, various ball bearing units and rod end bearings. Our advantage is to meet customer's special requirement per their application by different kind of material combination. The company has developed successfully all stainless steel mounted units, thermoplastic bearing housing, all stainless steel rod ends, slot injection molded rod ends, all plastic rod ends and zinc alloy miniature bearing units, etc., which have been widely used in different kind of industry and enjoy good reputation home and abroad.